Heat Exchangers

Heat exchangers transfer heat from one medium to another efficiently, including both mixed and unmixed media. Common applications for heat exchangers include refrigeration, space heating, air conditioning and use in power plants, petrochemical plants, petroleum refineries, natural gas processing, chemical plants, internal combustion engines and sewage treatment.

Heat exchangers are also used in the wine and brewery industries. Industrial use of heat exchangers often entails the heating and cooling of industrial processes on a large scale.

They can also be used to increase the fuel efficiency of aircraft. Industrial heat exchangers can additionally be used to save waste heat from being wasted, which can save on energy and thus money due to the reduced need for more external heat sources.

Whatever your industry and application is , G-tech will deliver the top quality heat exchanger by your specs right to your door

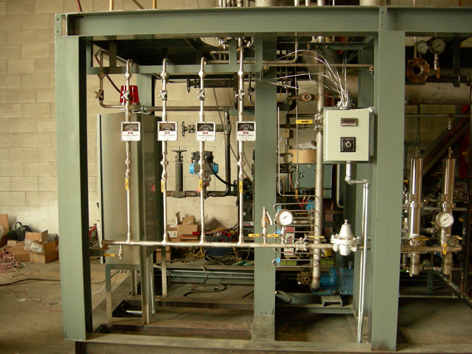

Shell and Tube Heat Exchangers

One common type of heat exchangers is shell and tube heat exchangers. These heat exchangers are very common in chemical plants and in petroleum refineries as well as other high-pressure applications. These are composed of large pressure vessels, here called shells, with a series of tubes operating inside.

Different fluids flow through the tubes and through the shell to generate the heat transfer process. These fluids are set at different starting temperatures. These fluids can be liquids or pressurized gases. Larger heat exchangers transfer heat more efficiency, since they provide more surface area in shell size and tube size. More tubes inside a shell also increase surface area and thus efficiency.

Different Types of Shell and Tube Heat Exchangers

One-phase heat exchangers, which are also known as single-phase heat exchangers, use only either liquids or gases. Two-phase heat exchangers can heat a liquid into a gas or vapor by boiling it. These are also called boilers. Two-phase heat exchangers can also condense a gas into a liquid by cooling a vapor. These are called condensers.

Power plants that generate power using steam-driven turbines may use both, with shell-and-tube boilers turning water into steam and shell-and-tube surface condensers condensing steam exhaust into water after it exits the turbine to be reintroduced into the turbine and reused. This recycled water then turns back into steam, and back again and again.

More on Shell and Tube Heat Exchangers

Tubes in heat exchangers are constructed of materials with good thermal conductivity, or a high ability to conduct heat. Heat moves from hot materials to cold materials. Tubes will thermally expand as part of the heat transfer process, so these tubes must also be able to withstand thermal stresses. It is also important for both the tubes and the shell to be able to undergo stresses from high pressure conditions, since fluids under pressure are often used in heat exchangers.

Withstanding corrosion stresses from fluids with different pH levels may also be necessary. Impact resistance is also a plus due to the possibility of an explosion because of materials under pressure.

Leaks that do not lead to explosions can also cause the functioning of the heat exchanger to fail and can interfere with the industrial process in question due to this failure and also due to fluid cross-contamination.

Shell and Tube Heat Exchangers in Practice

Common materials in shell and tube heat exchanger construction are metals like stainless steel, carbon steel, copper alloy, non-ferrous copper alloy, nickel, titanium and other metallic alloys.

Heat exchangers are quite commonly used to cool oil and hydraulic fluid in internal combustion engines, as well as the cooling of transmissions and hydraulic power packs.

Shell and tube heat exchangers are also relatively simple and easy to service.

Check our product page for the samples.